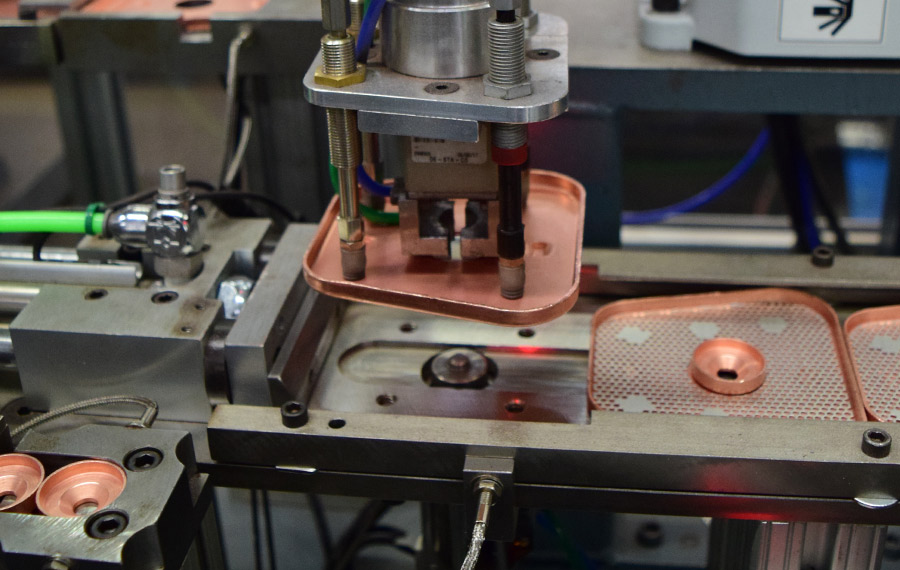

When volume is sufficient, many metal parts lend themselves to be efficiently manufactured through the use of progressive stamping tools. This type of high volume metal stamping manufacturing eliminates the need for multiple tool sets, presses, set-ups and operators, combining everything into one tool.

This is achieved by the automatic feeding of metal into a press through several tool stations, with each station performing a different operation(s). The part is carried through the tool by the web of raw material, which is designed to hold the part in position as it progresses from station to station.