Metallon has been committed to producing parts and high-volume assemblies that meet all of our customers’ requirements and expectations from our Thomaston, CT location since 1964. Our world-class engineering department leverages Solidworks 3D and Auto CAD and offers Product Design Assistance and Re-Engineering services, with quick turn Prototype parts.

Our modern in-house tool room allows us to vertically integrate, keeping all manufacturing processes, with the exception of finishing, in-house and keeping your costs down. With press capabilities ranging from 16 to 150 tons, you can be assured that no job is too tough for Metallon.

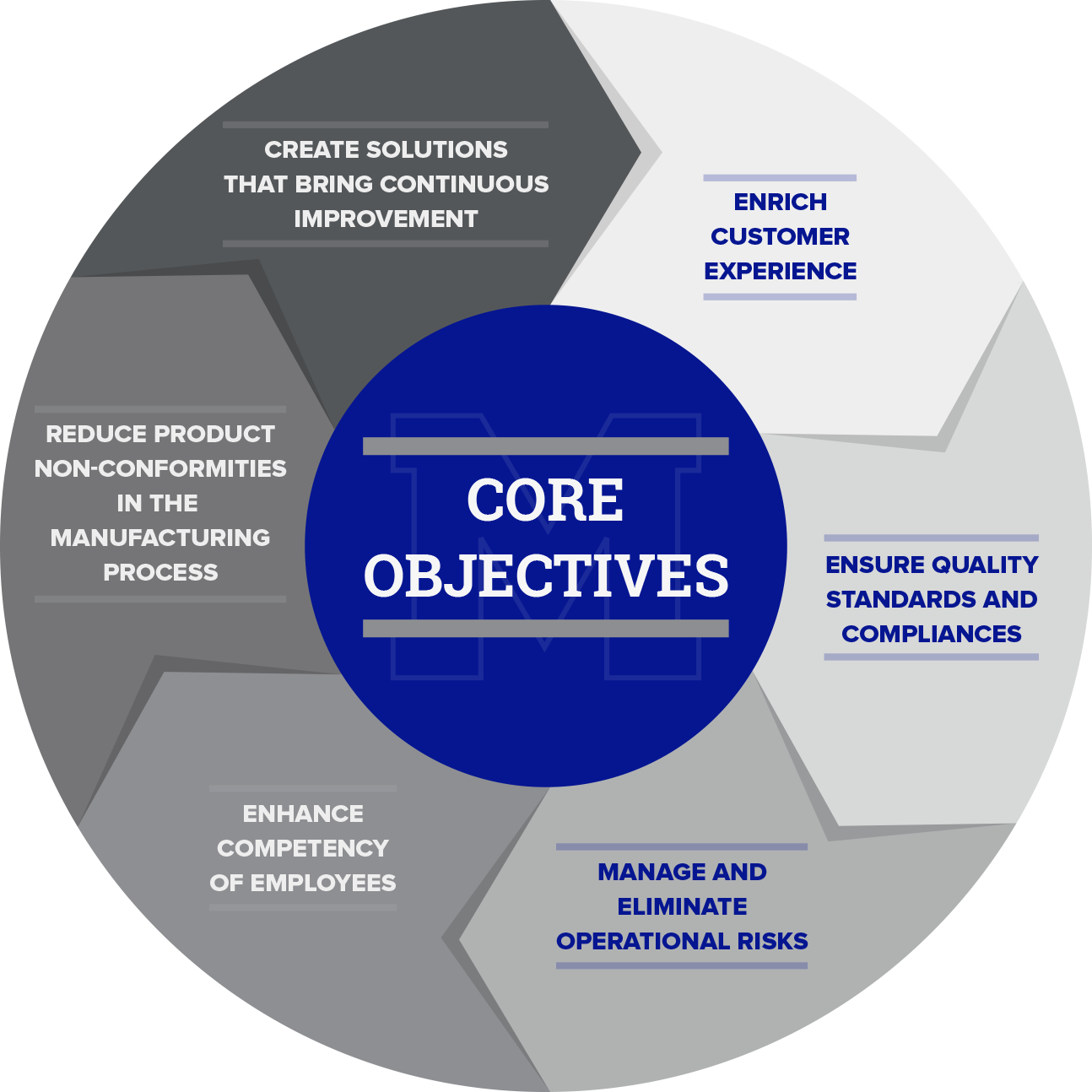

Additionally, we’re incredibly dedicated to quality, with quality systems to IATF16949-ISO9001-ISO14001, as well as our own strict in-house standards.

EXPERIENCE

- Developed and manufactured many precision metal stamped products.

- Significant manufacturing experience in high volume stamped products.

- Continuous ongoing working relationships with OEM, Tier 1 and Tier 2 suppliers.

RESOURCES

- Engineering support available for our customers.

- Tool room for progressive die building and automated assemblies.

- Manufacturing capacity to meet the long term needs of our customers.

ECONOMICS

- Competitive pricing.

- Value-added services.

- Committed to a long-term cost partnership.